Ultrasonic Semiconductor Chip Spraying

Ultrasonic Semiconductor Chip Spraying. Semiconductor chip: A semiconductor device that is etched, wired, and fabricated to perform a certain function on a semiconductor wafer.

Coating liquid: A mixed liquid composed of three main components of a photosensitive resin, a sensitizer and a solvent. After the photosensitive resin is irradiated, the photocuring reaction can be quickly performed in the exposed region, so that the physical properties of the material, particularly solubility, affinity, and the like are significantly changed. The soluble component is dissolved by appropriate solvent treatment to give the desired image.

Ultrasonic advantage: The photoresist coating needs to be very uniform and the coating thickness is in the range of 20-30 um. Ultrasonic contrast is controllable compared to conventional high pressure spray, and the degree of uniformity is better.

Recommended Equipment

Ultrasonic Atomization Nozzle

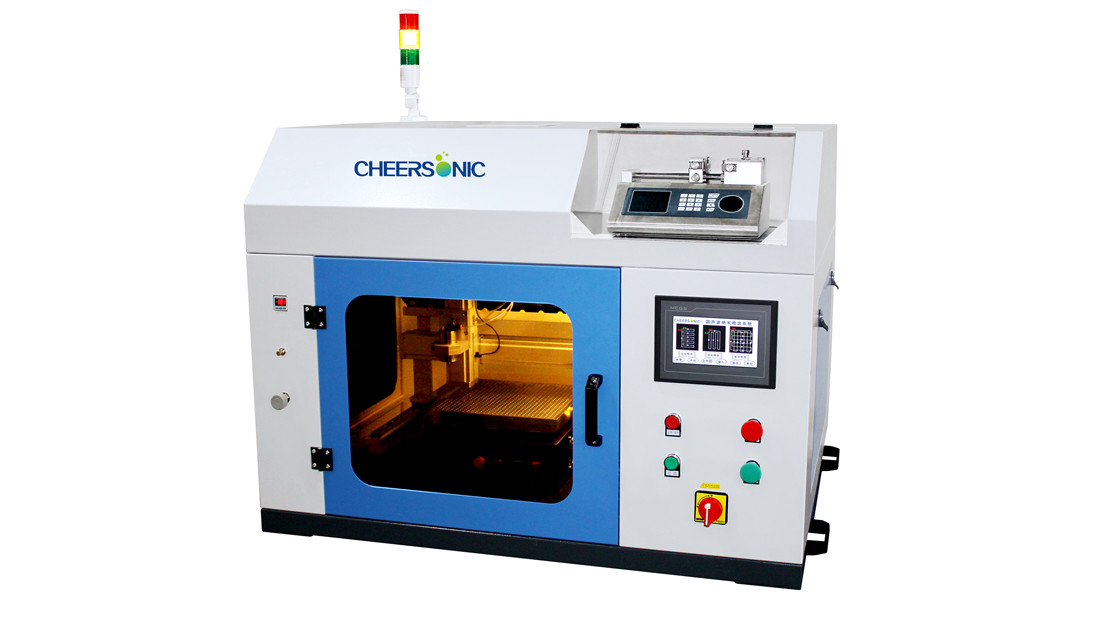

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor