PEM Fuel Cell Bipolar Plates Coating System

PEM Fuel Cell Bipolar Plates Coating System

Fuel cells are known for their environmentally friendly pollution-free, low moving parts, low temperature start-up, low noise, and high energy conversion efficiency. They are the most promising high-efficiency energy conversion devices.

When the proton exchange membrane fuel cell (PEMFC) is operated, under the action of the catalyst, the reaction occurs: 2H2+O2-→H20, and the generated non-polluted water is directly discharged or re-recycled for humidifying the gas, and the electrode reaction is generated. The electrons pass through the external circuit to the cathode, so that work can be done externally.

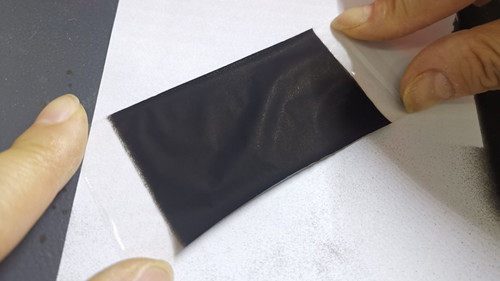

Ultrasonic coating systems produce highly durable, uniform, coatings of carbon-based catalyst inks onto both fuel cell and electrolysis processes for proton exchange membrane (PEM) electrolyzers such as Nafion, without deformation of the membrane. Uniform catalyst coatings are deposited onto PEM fuel cells, GDLs, electrodes, various electrolyte membranes, and solid oxide fuel cells with suspensions containing carbon black inks, PTFE binder, ceramic slurries, platinum and other precious metals.

Fuel Cell Catalyst Coating Systems Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor