Ultrasonic Spray Fluxing System

Product Description

Cheersonic’s CFLX-L ultrasonic flux spraying equipment, applicable to a full range of ultrasonic spray nozzles, suitable for spraying wave soldering flux development and production. Replace traditional air spraying and foam coating methods. Coating the Flux on electronic components and printed circuit boards, providing a high-precision, high-performance coating method. It integrates ultrasonic nozzle, ultrasonic control and high-precision liquid supply system control. The equipment can be used for large-area coating, selective spraying in special areas, and can be directly embedded into existing wave soldering systems. Compatible with all fluxes, high liquid utilization, uniform sprayed surface.

Key Features

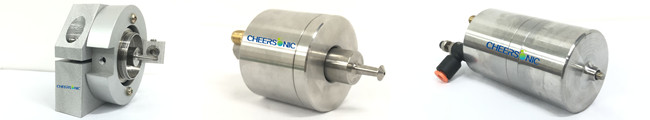

• Ultrasonic nozzles

• Nozzle corrosion resistance

• The nozzle is not easy to be blocked

• Spray range in 2-100mm diameter

• Applicable to all fluxes

• High control accuracy, spot spraying and fast startup speed

• Equipment is stable and maintenance costs are low

• Coating utilization> 95%

• Low diversion pressure and no sputtering

• Can be equipped with multiple series nozzles

• Spray special-shaped workpiece

Application

• Electronic components

• Printed circuit boards

Parameter

| Ultrasonic spraying system | Ultrasonic nozzle mode (Optional multiple nozzles)Maximum spraying width: 400mmParticle size: 10-40umFlow rate: 0.5-70ml/min | Ultrasonic dispersion | Ultrasonic dispersion tank for pre-dispersion of liquidsUltrasonic dispersion syringe,Keep the suspension evenly dispersed during the spraying process |

| Liquid utilization rate | 95% | Plasma-spraying | Pre-surface treatment of samples |

| Spray uniformity | 5% | Compressed air | <divClean, dry unlubricated air |

| Delivery system | Automatic sample in and out, width adjustable: 150-800mm | Certification | CE, ISO9001:2015 |

| Motion accuracy | ±0.1mm | Exhaust | Built-in exhaust system |

| Control system | Self-developed 6-axis control system, 7-inch full-color touch LCD screen, can be set to automatic mode, jog debugging mode, with security system | Power requirements | 220V, +/-10%, 50-60Hz,single phase |

| Motors | Digital AC servo motor drive | Dimensions | 2170*1000*1900 mm |

| Constant flow metering pump | Stable and constant liquid supply for 24 hours without manual fluid change | Weight | 600kg |