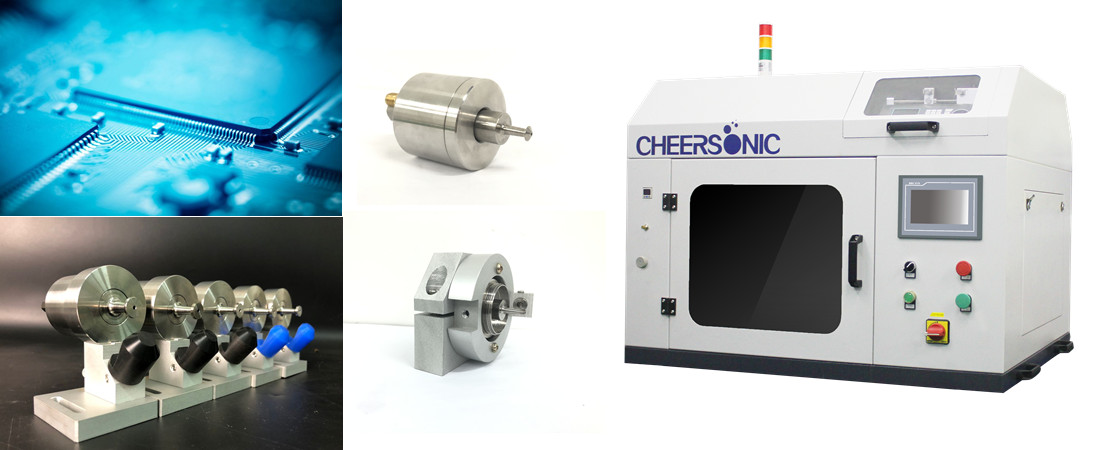

Ultrasonic Fluxing Systems

Ultrasonic Fluxing Systems

Ultrasonic Fluxing Systems

Select a machine to learn more

CFLX-S

CFLX-M

CFLX-L

CFLX-S

Cheersonic desktop type ultrasonic flux spraying equipment, applicable to a full range of ultrasonic spray nozzles, suitable for spraying wave soldering flux development and production. Replace traditional air spraying and foam coating methods. Coating the Flux on electronic components and printed circuit boards, providing a high-precision, high-performance coating method. It integrates ultrasonic nozzle, ultrasonic control and high-precision liquid supply system control. The equipment can be used for large-area coating, selective spraying in special areas, and can be directly embedded into existing wave soldering systems. Compatible with all fluxes, high liquid utilization, uniform sprayed surface.

CFLX-M

Cheersonic ultrasonic flux spraying equipment, applicable to a full range of ultrasonic spray nozzles, suitable for spraying wave soldering flux development and production. Fully automatic multi-axis ultrasonic solder spray flux system with precise selective area flux function. It has been proven to reduce flux consumption by up to 93%. The system is designed for medium-to-high mixed production lines and allows immediate changes to the spray area required. The system is provided in a stand-alone format and can be easily installed in front of any wave welder.

CFLX-L

Inline ultrasonic solder spray flux system with precise selective area flux function. It has been proven to reduce flux consumption by up to 93%. Stationary ultrasonic spray fluxing system for low mix / dedicated lines with medium to high volume. The system is provided in a standalone format and can be easily installed in front of any wave soldering machine. Ultrasonic spray systems feature non-clogging, repeatable, low maintenance ultrasonic spray performance with up to 80% reduction in flux consumption.

Ultrasonic spray fluxing for printed circuit board manufacturing

Cheersonic’s ultrasonic sprayer is an alternative flux system for selective soldering machines. The ultrasonic spray system is designed to solve the main problems of most standard fluxes, such as spray and air pressure spray. The ultrasonic spray system will spray all flux without clogging, increasing accuracy, increasing production speed and reducing overspray.

Fully automatic multi-axis ultrasonic solder spray flux system with precise selective area flux function. Advanced dot programming capabilities; simply import an image of the PCB and highlight areas that require flux. Ideal for trays and PCBs with unnecessary flux. It has been proven to reduce flux consumption by up to 93%.

The fully automatic multi-axis ultrasonic solder spray flux system has advanced spray accuracy, and the maintenance amount is reduced by 95% compared with the traditional pressure spray flux. All fully automatic multi-axis ultrasonic solder spray flux systems have ultrasonic spray performance that is non-blocking, repeatable, and low-maintenance.

Ultrasonic Spray Fluxing Systems Features:

Ultrasonic nozzles

Nozzle corrosion resistance

The nozzle is not easy to be blocked

Spray range in 2-100mm diameter

Applicable to all fluxes

High control accuracy, spot spraying and fast startup speed

Equipment is stable and maintenance costs are low

Coating utilization> 95%

Low diversion pressure and no sputtering

Can be equipped with multiple series nozzles

Spray special-shaped workpiece